The Buzz on Water Purifier For Well Water

Table of Contents10 Simple Techniques For Water Purifier For Well WaterThe Greatest Guide To Water Purifier For Well WaterSome Known Questions About Water Purifier For Well Water.The Buzz on Water Purifier For Well Water

A phosphorous compound is added to aid regulate deterioration of pipes. This helps stop lead and copper that may be present in pipes from seeping into the water. As the water leaves the plant, ammonia is included in change the chlorine to chloramine, a disinfectant that keeps a recurring in the distribution system against microbial contamination.All chemicals that are included are certified food quality, secure for use in foods. Treated water is kept in deep underground tanks as well as also moves by gravity to pumping terminals and also right into the distribution system. The distribution system is composed of 1,960 miles of water pipe ranging in size from 4" to 60".

Elimination of taste and smell compounds from the water.: Softens the water.: Filtering to eliminate small particles and sanitation to eliminate viruses and also microorganisms, as well as make certain an inappropriate environment for infection and microorganisms development throughout the distribution system.

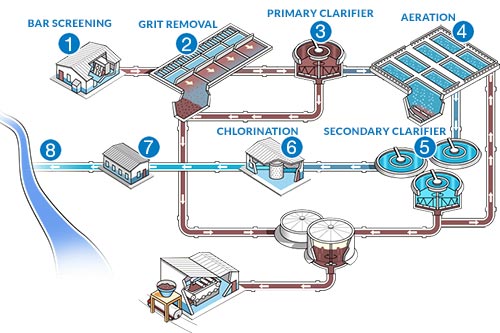

Eight Stages of the Wastewater Refine Stage One Bar Screening Elimination of large items from the influent to avoid damages to the center's pumps, shutoffs and also various other equipment. The process of treating as well as redeeming water from wastewater (any water that has been used in houses, such as flushing toilets, washing recipes, or showering, as well as some water from commercial use as well as tornado sewage systems) begins with the expectation that after it is treated it will certainly be clean adequate to reenter the setting.

The Buzz on Water Purifier For Well Water

According to the EPA, The Tidy Water Act (CWA) establishes the standard structure for regulating discharges of contaminants into the waters of the United States and managing quality requirements for surface area waters. Under the CWA, EPA establishes wastewater standards for market. The EPA has actually likewise established nationwide water high quality standards suggestions for contaminants in surface waters.

This begins in the aeration container. The primary feature of the aeration storage tank is to pump oxygen into the tank to motivate the failure of any kind of organic material (and the growth of the bacteria), in addition to guarantee there is adequate time for the organic material to be broken down.

10 Easy Facts About Water Purifier For Well Water Explained

This process is managed to supply the ideal problems for bacterial growth. Dissolved oxygen surveillance at this phase of the plant is vital. Ammonia as well as nitrate measurements are common to gauge just how efficient the microorganisms are in converting NH3 to N2.

Stage 5 Second Clarifier Treated wastewater is pumped right into a secondary clarifier to permit any type of continuing to be natural debris to resolve out of cured water circulation. As the influent leaves the oygenation process, it moves into a secondary clarifier where, like the primary clarifier, any type of extremely small solids (or penalties) sink to the bottom of the storage tank.

Component of this turned on sludge is returned to the oygenation container to enhance the bacterial focus, assistance in proliferation, and speed up the breakdown of natural product. The excess is disposed of. The look at more info water that moves from the secondary clarifier has considerably lowered organic material as well as needs to be approaching anticipated effluent specs.

With the enhanced concentration of microorganisms as component of the aeration stage, there is a requirement to evaluate the outbound effluent for germs existence or absence and also to disinfect the water. This makes sure that more than defined concentrations of microorganisms are page not launched into the environment. Chlorination is one of the most typical and also low-cost kind of disinfection however ozone as well as UV disinfection are additionally boosting in appeal.

Our Water Purifier For Well Water Diaries

After adequate time, fragments adhere to each various other and also expand into bigger bits, or, floc, which is susceptible to work out in water. Explanation of water is completed by the seperation of suspended solids from water by gravity.

The cleared up water steps up gradually, ultimately overlooking the effluent weir to the cone outlet as well as on the to filters for additional treatment. The water plant incorporates a solitary stage lime softening operation look at more info to get rid of firmness. Solidity is triggered by the existence of dissolved bivalent and polyvalent steel ions, predominantly calcium and also magnesium.

This is included both in the clearwell as well as the high solution discharge as water gets in the distribution system. water purifier for well water. Hydrofluosilicic acid offers the resource of fluoride, which is helpful in the prevention of dental cavity in kids. A fluoride concentration of 1. 1-1. 2 mg/l is normally preferable in the plant tap.